Ufanisi machine project

Special loan brings savings and gains to Tanzanian farmers

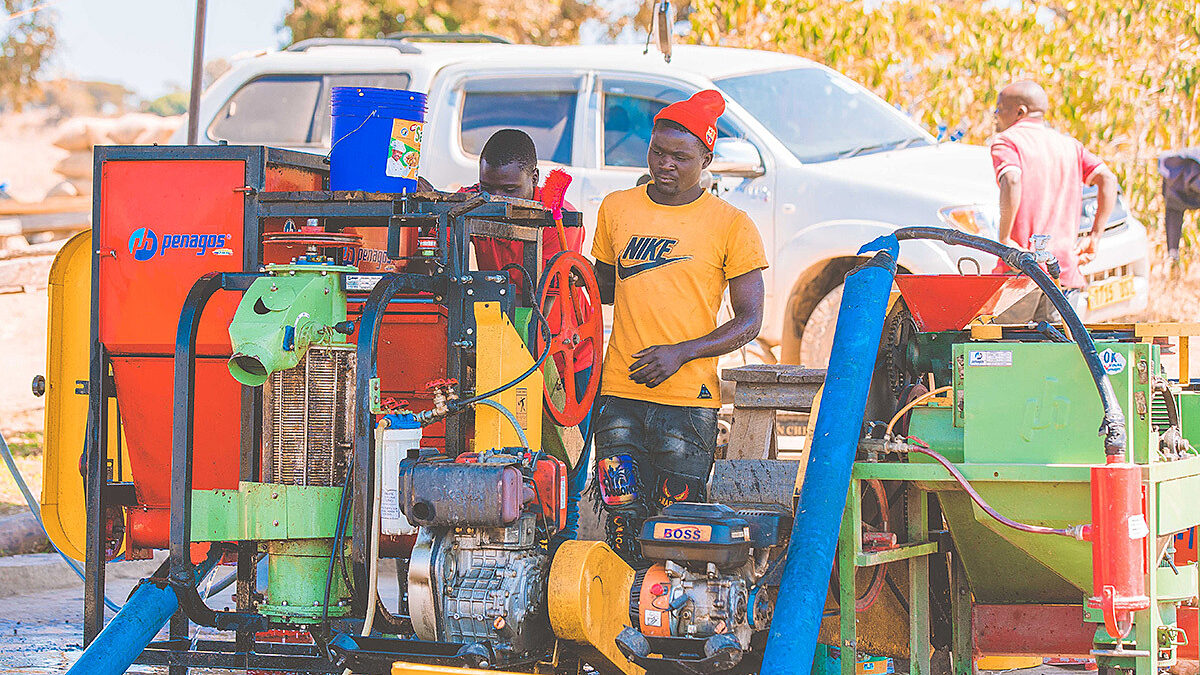

The new coffee pulping unit (CPU) at the Iyenga AMCOS in Mbozi.

Tanzanian cooperatives are installing eco-pulpers with the help of a no-interest loan facility

Ufanisi is the Swahili word for ‘efficiency’, a fitting name for a project run by Taylor Winch Tanzania (Volcafe’s company in the country) that brings effort-saving machinery to coffee communities. Through the Ufanisi Machine project, Taylor Winch created an interest-free loan that enables Tanzanian cooperatives to acquire specialised Coffee Pulping Units (CPUs) for the collective benefit of their members.

To date, over 1200 farming families at three cooperatives have gained access to highly efficient CPUs, helping to improve the quality of their coffee and fetch higher earnings.

Quick facts

Country: Tanzania

Objectives: Enable AMCOSs (cooperatives) to acquire energy-efficient coffee pulping units (CPUs) that save time, boost coffee quality, and fetch higher prices for farmers, through an interest-free loan facility.

Timeline: 2020 onwards

Impact: To date, three AMCOS representing some 1200 members have accessed the revolving Ufanisi loan to install CPUs. The CPUs reduce the time spent on pulping/processing coffee by upwards of 50 percent, while using as much as 50 percent less water.

In Tanzania, farmers work together as members of Agricultural Marketing Cooperative Societies (AMCOSs). Through an AMCOS, farmer-members can economise on purchasing agricultural inputs and supplies, and the cooperatives also help to market their crops more efficiently.

The Ufanisi project came about as a means to creatively employ some leftover funds from a completed project on gender equity and coffee quality that specialist investor AgDevCo and Taylor Winch Tanzania had carried out. The partners agreed to put the remaining funds into a rotating loan facility which would allow AMCOSs to acquire and install a CPU for their members. The AMCOS then repays the interest-free loan over three growing seasons, allowing the funds to be re-lent to another AMCOS.

The project offers a labour-saving piece of machinery that can benefit all the members of an AMCOS. Harvested coffee cherries are poured into the machine, which pulps (or removes the outer layer of) the cherries. The machine also removes the mucilage of the beans (a sticky inner layer), helping the AMCOS to use fewer fermentation tanks.

The CPUs being installed through the Ufanisi loans are built by Penagos, a Colombian manufacturer known for their energy-efficient designs. The machines the AMCOSs have installed can process either 1200kg or 2500kg of cherries per hour, reducing the labour time involved from as much as 7-10 hours to only 4-5 hours for the same amount of coffee. Beyond saving farmers time from manual processing, the CPUs also use significantly less energy and water, lowering the overall carbon footprint of the AMCOS and conserving water in regions prone to shortages.

The first AMCOS to acquire a CPU through the Ufanisi loan was the Iyenga AMCOS in Mbozi, southern Tanzania. Their new machine arrived midway through the harvest season in 2020 and made an immediate impact for Iyenga, yielding higher quality beans than their older unit. The 350 farmers at the AMCOS have already repaid the loan.

Juhudi Watson Mwamengo, Iyenga AMCOS

'Before we received our new CPU machine, we had a small pulping machine with little capacity that required us to work really late to complete all daily deliveries to farmers,' says Juhudi Watson Mwamengo from Iyenga AMCOS.

'This really affected our quality, as sometimes we had coffee left overnight. Additionally, we have water shortages in our village, so this machine has really helped us as it uses less water and takes less time to process a lot of coffee,' notes Juhudi.

'As a result, our quality has improved, and our income has also increased.'

Beyond saving farmers time from manual processing, the CPUs also use significantly less energy and water

Osward Mdolo, Heyza AMCOS

In 2021, the 250 farmers of the Heyza AMCOS, also in Mbozi, installed a CPU through the Ufanisi loan, and in 2022 the 500 farmers of the Maki AMCOS in the southern district of Mbinga acquired a CPU.

'Here at Hezya AMCOS, we used to produce home-processed coffee, in which each farmer pulped their coffee at home using local pulping machines,' says farmer Osward Mdolo.

'Because of the machine installed through this [project] by Taylor Winch Tanzania, we are now able to certify our coffee and sell it in the specialty market at a higher price. As farmers, this has increased our income.'

Juma Salum, Volcafe Way programme coordinator

'We were pleased to introduce the Ufanisi Machine project to the farmers,' explains Juma Salum, a field officer and Volcafe Way farmer support programme coordinator.

'This has helped operations at the CPU, as before the farmers were overwhelmed with the daily deliveries, and the new installation has improved this a lot, from time efficiency to less usage of water to improving the quality of the coffee.'

CPUs bring cost and labour savings to farmers, but most smallholders could not afford to acquire one on their own. Through the Ufanisi loan facility, Volcafe in Tanzania is helping make it possible for more and more coffee cooperatives to acquire an efficient, ecological pulping unit that benefits their entire community.

Marie Renou-Ullrich, Head of Marketing and Communications, email hidden; JavaScript is required